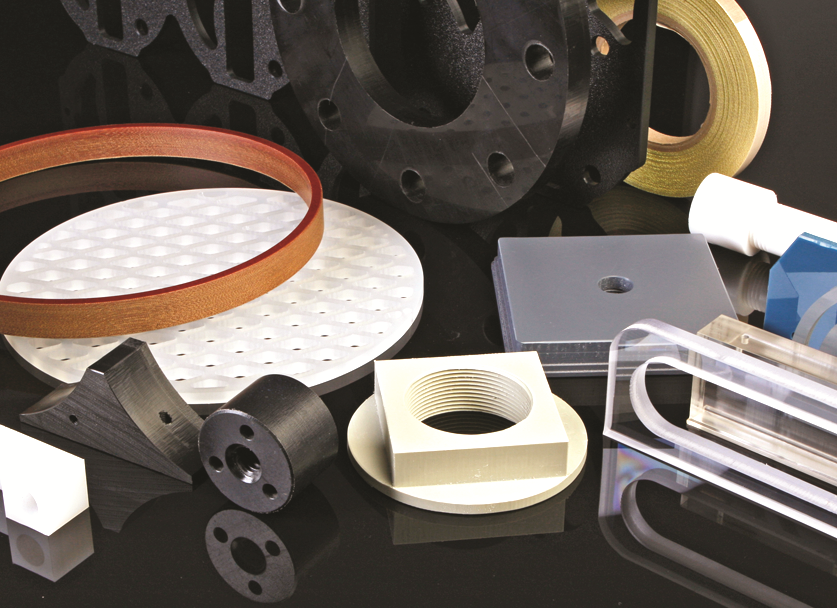

At Aetna’s state-of-the-art fabrication facility, we take pride in our extensive machining capabilities, which enable us to create close-tolerance plastic parts that consistently meet and exceed our customers’ expectations. With a diverse array of machinery at our disposal, including a 5-axis router, a 3-axis router, multiple mills, and a lathe, we have the tools and expertise to bring your machining projects to life.

MACHINING TOOLS

5-Axis Router

Our 5-axis router is a versatile and high-precision machine that allows us to create complex, intricate plastic parts. The five-axis capability means we can manipulate the workpiece from multiple angles, resulting in greater flexibility and accuracy. Whether it’s engineered parts for packing, food & beverage, OEM equipment, or medical, this machine is capable of handling a wide range of plastic materials and geometries.

3-Axis Router

Our 3-axis router is a workhorse in our machining lineup, ideal for projects that require precision and efficiency. While it may not offer the same level of complexity as the 5-axis router, it excels in delivering consistent results for less intricate parts. Its speed and reliability make it an excellent choice for batch production runs or rapid prototyping.

Milling Machines

We have two milling centers in our facility, each tailored to specific machining needs. These mills are well-suited for tasks such as cutting, drilling, tapping, and contouring plastic materials. Their robust construction and versatility allow us to tackle a variety of milling projects efficiently.

Lathe

Our lathe is an essential tool for turning and shaping cylindrical or rotational parts. It is particularly useful for producing components like plastic shafts, rollers, bushings, and fittings. With the lathe’s precision control and skilled operators, we can create parts with tight tolerances and smooth finishes.